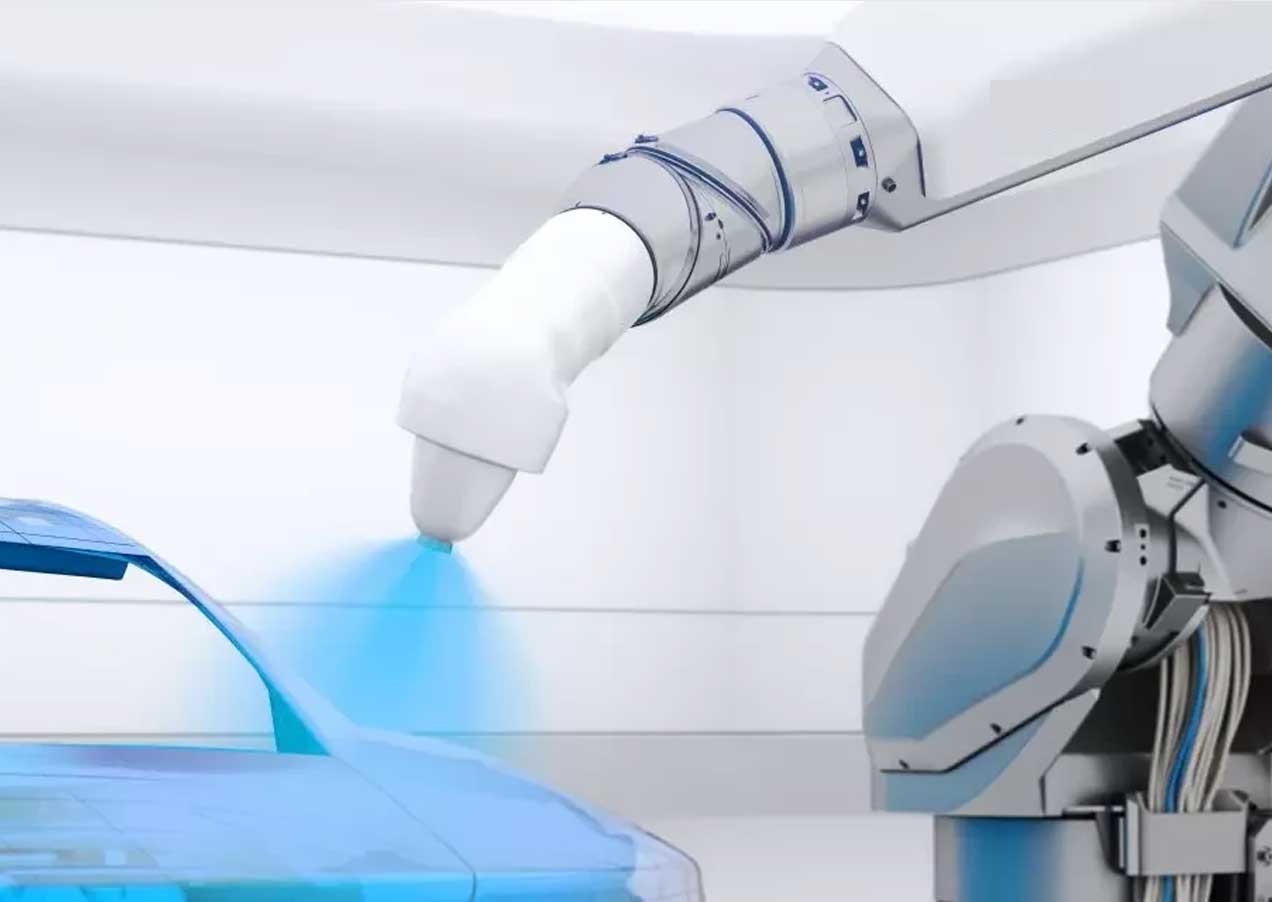

The Core Painting System – Fully Automatic Painting is a high-efficiency solution designed for consistent and uniform application of refractory coatings on sand cores. This system automates the entire painting process—including core handling, coating, draining, and drying—ensuring high productivity, reduced labor dependency, and superior coating quality. It is ideal for medium to large-scale foundries focused on improving casting accuracy and surface finish.

- Fully Automated Operation for painting, draining, and drying.

- Uniform and Consistent Coating with minimal overspray.

- High Productivity suitable for mass production environments.

- Automated Core Handling reduces manual labor and handling time.

- Adjustable Spray Parameters for different core sizes and coating thicknesses.

- Integrated Drying System for quick and efficient drying.

- Closed-Loop Coating System for minimal wastage and cleaner operation.

- Programmable Logic Controller (PLC) for process automation and monitoring.

- Improves Casting Quality by enhancing surface finish and reducing defects.

- Ideal for Water-Based and Solvent-Based Coatings.